- General Top View

-

SEMICONDUCTOR View

-

ApplicationsAutomotive

Body Electronics

xEV

In-Vehicle Infotainment

Advanced Driver-Assistance Systems (ADAS)

Chassis

IndustrialInfrastructure

BEMS/HEMS

Factory Automation

Commercial Equipment

Consumer/PersonalIoT Equipment

Healthcare

Wearable Device

Mobile

Computer Peripherals

-

Products

Products

-

Design & Development

-

Knowledge

Knowledge

- Where To Buy View

-

- STORAGE View

- COMPANY View

- Part Number Search

- Cross Reference Search

- Keyword Search

- Parametric Search

- Stock Check & Purchase

This webpage doesn't work with Internet Explorer. Please use the latest version of Google Chrome, Microsoft Edge, Mozilla Firefox or Safari.

require 3 characters or more.

The information presented in this cross reference is based on TOSHIBA's selection criteria and should be treated as a suggestion only. Please carefully review the latest versions of all relevant information on the TOSHIBA products, including without limitation data sheets and validate all operating parameters of the TOSHIBA products to ensure that the suggested TOSHIBA products are truly compatible with your design and application.

Please note that this cross reference is based on TOSHIBA's estimate of compatibility with other manufacturers' products, based on other manufacturers' published data, at the time the data was collected.

TOSHIBA is not responsible for any incorrect or incomplete information. Information is subject to change at any time without notice.

require 3 characters or more.

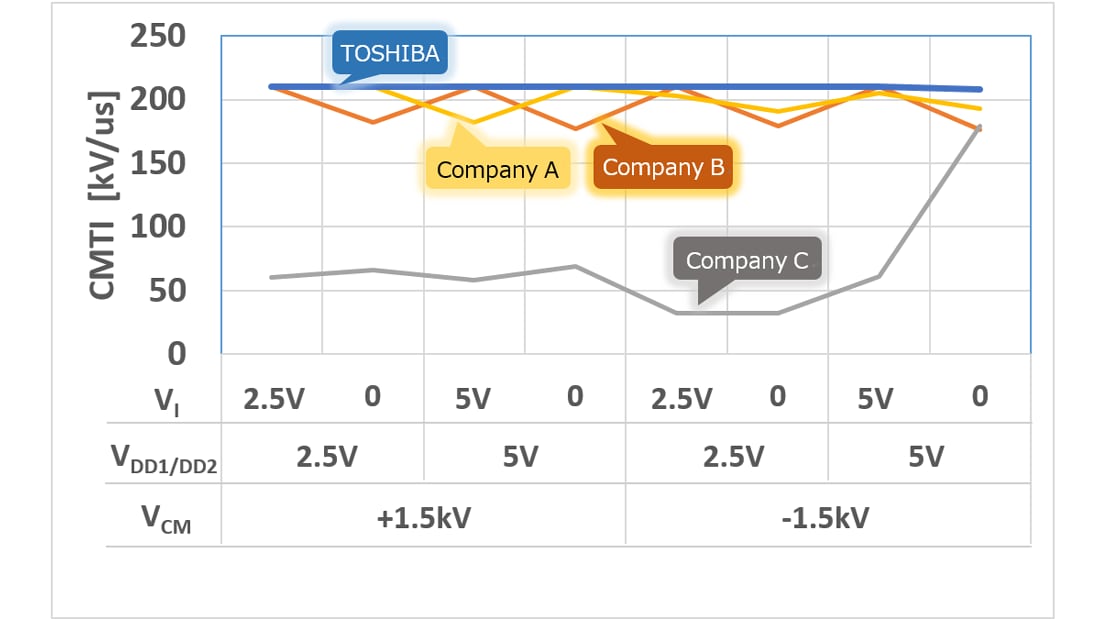

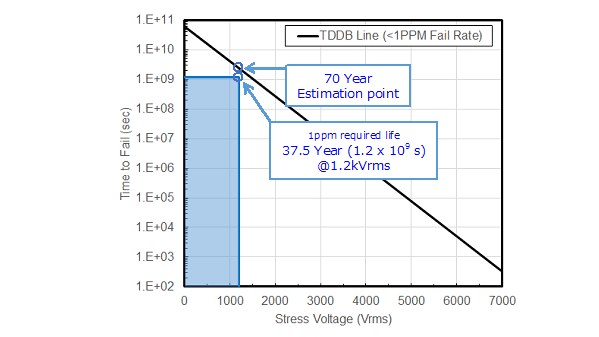

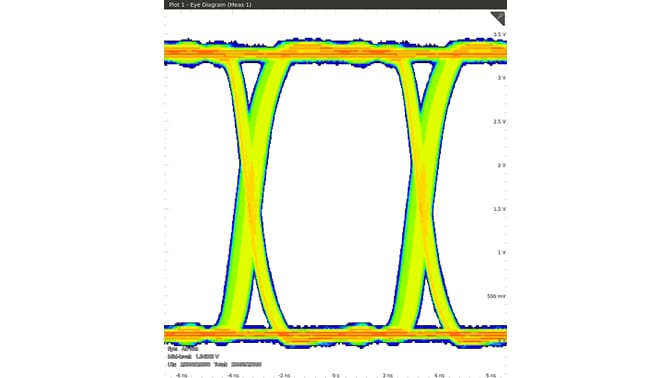

Standard Digital Isolator with Robust Electromagnetic Compatibility (EMC)

As Factory Automation (FA) progresses, functionality such as inverters/servos and PLCs are often integrated into the same system.

Because of this, there is a risk of noise interference in switching operations such as inverters/servos that control motors. Therefore, the FA market must eliminate the risk of this noise interference as much as possible to operate FA equipment safely and accurately. Toshiba's standard digital isolators are designed to meet the market's demands and contribute to improving customer product reliability by ensuring solid electromagnetic compatibility (EMC*1) that is as noise-free as possible and less susceptible to external noise at the semiconductor level.

(Indicates whether the equipment or system is causing electromagnetic disturbances and whether it is free of electromagnetic interference or works appropriately in the event of such interference.)

Reference: Please refer to the following information on semiconductor EMC and our semiconductor EMC testing laboratory.

Technical Review: Toshiba EMC testing laboratory receives ISO/IEC 17025 accreditation (701.5KB)

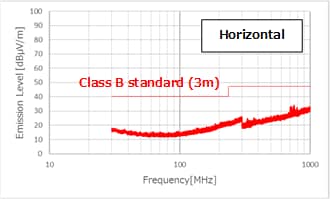

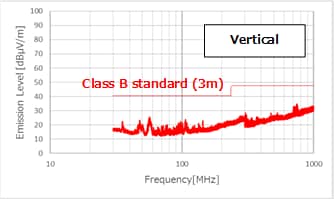

EMI*2: Reference test condition CISPR32*3

A margin of at least 10dB is ensured for Class B (3m) standards, which are more stringent than Class A (3m).

- A smaller value means less noise is generated.

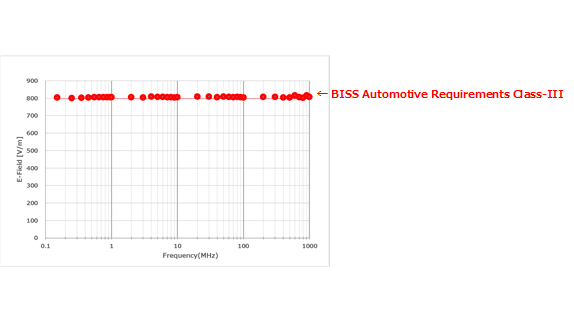

EMS*2 IEC 62132-8: Reference test conditions*4

BISS*5 800V/m noise of in-vehicle requirement class-III does not cause malfunction.

- The higher the value, the more significant is the interference from outside noise.

*1: EMC: Electro Magnetic Compatibility.

*2: EMI/EMS: Electromagnetic Interference / Electromagnetic Susceptibility.

*3: CISPR32: Emission requirements for multimedia equipment.

*4: IEC 62132-8: Semiconductor EMC test standard (radiation immunity: IC Stripline method).

*5: Common specifications for semiconductor EMC testing formulated by BISS: Bosch, Infineon, and Siemens (now Continental).

[Caution] Refer to each specification sheet/specification sheet for the contents of the reference test conditions.

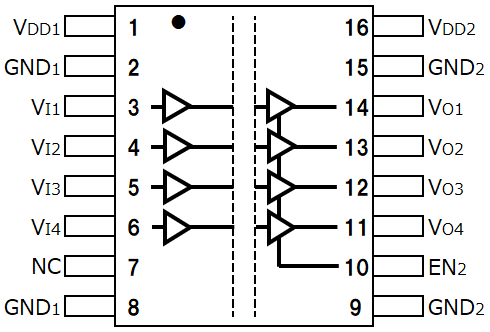

Standard Digital Isolators

Related information

Queries about purchasing, sampling and IC reliability

Stock Check & Purchase

require 3 characters or more.

| Part Number | Authorized Distributor | Stock Quantity | Date | Shopping Cart |

|---|

Through this website you are able to proceed to the website of our distributors ("Third Party Website") which is not under the control of Toshiba Corporation and its subsidiaries and affiliates (collectively "Toshiba"). The Third Party Website is made available to you as a convenience only and you agree to use the Third Party Website at your own risk. The link of the Third Party Website does not necessarily imply a recommendation or an endorsement by Toshiba of the Third Party Website. Please be aware that Toshiba is not responsible for any transaction done through the Third Party Website, and such transactions shall be subject to terms and conditions which may be provided in the Third Party Website.